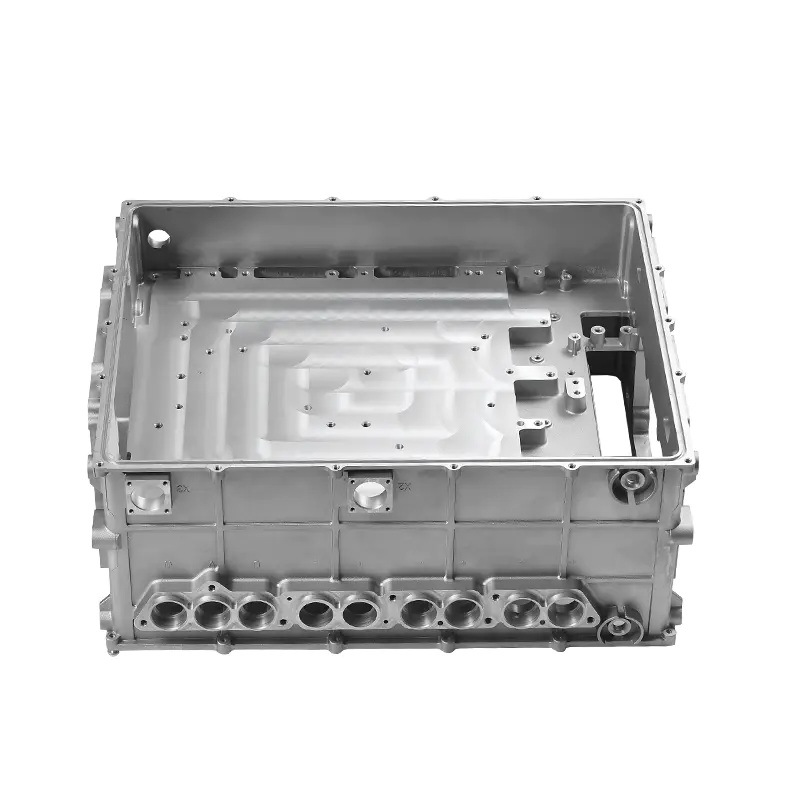

O carcaça da caixa de velocidades desempenha um papel fundamental de suporte e proteção em todo o sistema da caixa de câmbio, e seu design afeta diretamente a rigidez e a resistência ao impacto da caixa de câmbio. A estrutura razoável e a seleção de materiais podem garantir que a carcaça permaneça estável quando submetida a impactos externos e cargas internas, melhorando assim o desempenho geral e a vida útil da caixa de engrenagens.

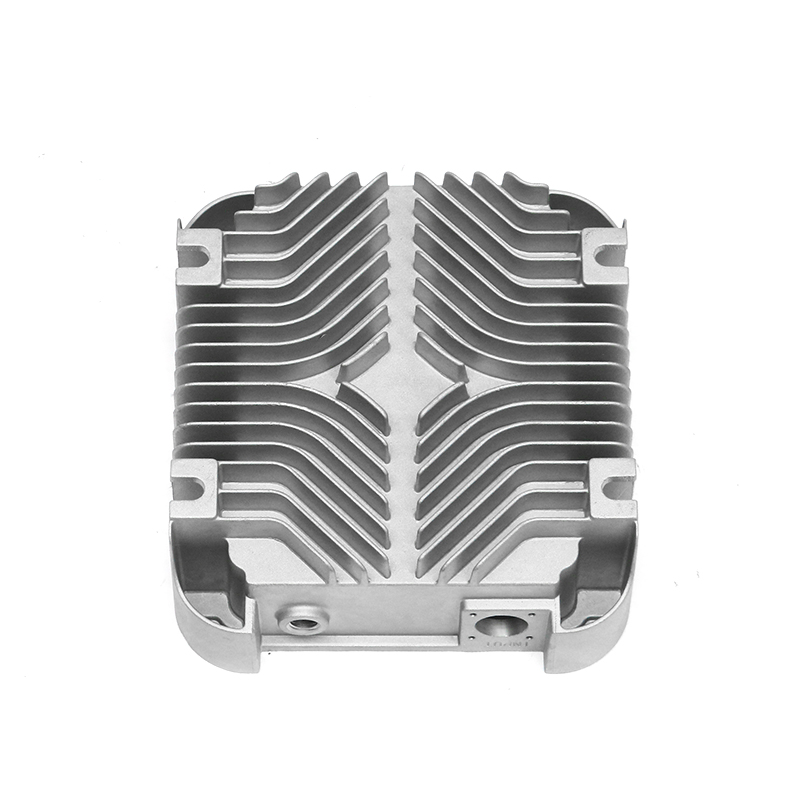

Uma carcaça de alta rigidez pode reduzir a deformação da caixa de engrenagens causada por vibrações e mudanças de carga durante a operação, melhorando assim a estabilidade da transmissão de potência. Quando a caixa de engrenagens está funcionando, o engate interno da engrenagem gerará uma grande força, o que requer suporte suficiente da carcaça, caso contrário, poderá causar desalinhamento ou desgaste anormal das peças internas da caixa de engrenagens. Portanto, o projeto estrutural da carcaça precisa distribuir razoavelmente os pontos de apoio para que possa suportar uniformemente forças de diferentes direções, evitar concentração de tensões locais e garantir que a caixa de engrenagens possa permanecer estável sob diversas condições de trabalho.

O impact resistance of the housing is also crucial, especially in complex use environments, where the gearbox may be subjected to severe external impacts, such as bumps on the road, sudden changes in load or other external forces. If the housing is not impact-resistant enough, it may be deformed due to external impacts, and even affect the normal operation of internal parts. Therefore, in the design of the shell, materials with a certain toughness are usually used so that they can effectively absorb energy when impacted instead of directly transferring it to the internal structure. In addition, a reasonable structural layout, such as reinforcing ribs or multi-layer support structures, can further enhance the shell's impact resistance, so that it can still maintain normal operation in sudden situations.

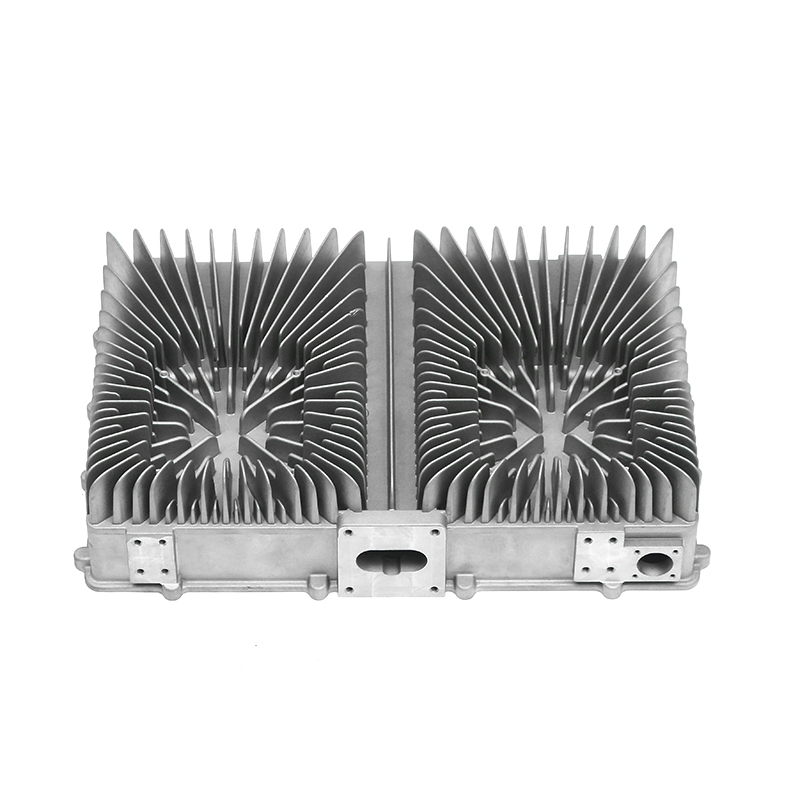

O choice of materials has an important impact on the rigidity and impact resistance of the shell. Usually, the shell is made of high-strength metal materials, so that it has good impact resistance while providing sufficient support. Different processing methods will also affect the final performance of the shell. For example, the casting process can improve the density of the material, thereby improving its strength and durability, while some special surface treatment technologies can enhance the shell's wear and corrosion resistance, so that it can maintain stable performance in different environments.

O internal structure design of the shell also needs to take into account the needs of rigidity and impact resistance. Reasonable internal reinforcement structure can effectively disperse the load, so that the shell is not easy to deform when subjected to external force. At the same time, certain support points are usually designed inside the shell so that it can fit more closely with the internal parts, thereby reducing loosening caused by impact or vibration. In addition, some housings are thickened in certain areas to enhance local bearing capacity, thereby improving the stability of the overall structure.

O design of the installation method and connection parts are also important factors affecting rigidity and impact resistance. A reasonable installation structure can ensure that the housing is tightly combined with other components to avoid affecting the normal operation of the gearbox due to looseness. At the same time, the fixing method of the housing needs to take into account the load changes in different environments to ensure that it will not be deformed or damaged due to stress accumulation during long-term use. In addition, some special connection methods, such as multi-point fixing or strengthening connectors, can also further enhance the stability and impact resistance of the housing.

Produtos recomendados

Os produtos fornecidos por empresas famosas são profundamente confiáveis pelos usuários.